|

|

Id: 9000-340

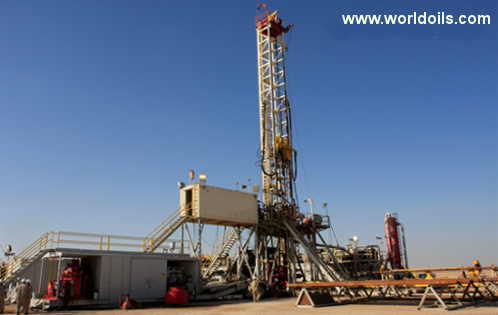

National 110UE Drilling Rig -1500 hp - for Sale

Worldrigs ID: WR25 Description

National 110UE 18,000' Drilling Rig

Newly Refurbished, 1500 HP Electric, +/- 18,000’ Capacity drilling rig

Drawworks :

National 110 UE 1500HP Single Drum Drawworks, Lebus Grooved

f/1-3/8” Line, Makeup & Breakout Catheads, with Petron Driller’s

Control Console, Crown-O-Matic. Drawworks is remanufactured

by major machine shop with warranty.

Drawworks Power :

Apollo 752 DC Traction Motor, S/N-7514175, 1000 HP, with Emerson

AB34 10 HP Electric Blower Assembly, S/N-YC10E1B1.

Apollo 752 DC Traction Motor, S/N-7505238, 1000 HP, with Emerson

AB34 10 HP Electric Blower Assembly, S/N-YC10E1B2

Brake :

Rade Tech 88058DS Electric Brake

Derrick :

Skytop 142’H Cantilever Beam Leg Mast, 1,000,000 Lb. Static Hook Load,

Pin-Type, SKYTOP Crown Block w/(6) Crown Sheave Cluster, Crown

Safety Platform, Racking Board, Tong Counterweights, Ladder, Derrick

Climber, Mast Stand, 3-1/2” Standpipe & Manifold. Mast and sub will be

reconditioned and API inspected by Superior Derrick Service. Both mast &

sub were built in 1981 but never put in service until 2006.

Substructure :

Skytop 28’W x 26’H x 72’L Swing-Up Substructure, 1,000,000 Lb. Casing

Load, 600,000 Lb. Setback Capacity w/Rotary Beams, V-Door Ramp, Type

EB Deadline Anchor, Stairs, Safety Rails.

Power Source :

Kato 1050 KW AC Generator, S/N-2782533447, p/b CAT D399 Diesel Engine,

w/Air Starter, Radiator, Gauges, Mounted on 10’W x 30’8”L Covered Skid.

Rebuilt and engines load tested.

Kato 1050 KW AC Generator, p/b CAT D399 Diesel Engine,

S/N-35B066244, w/Air Starter, Radiator, Gauges, Mounted on 10’W 30’8”L

Covered Skid. Rebuilt and engines load tested.

Kato 1050 KW AC Generator p/b CAT D399 Diesel Engine w/Air Starter, Radiator,

Gauges, Mounted on 10’W x 30’8”L Covered Skid. Rebuilt and engines load tested.

SCR Unit :

IDM 4-Bay SCR Unit, S/N-505622, w/9’2”L Porch, Switchgear & Instrumentation to

Control (3) 1050 KW AC Generators, Includes: (1) Brake Control Box, GE E-9000

Line Series Motor Control Center, Mounted in 10’3”W x 29’2”L Temperature-Controlled

House w/(2) Eubank V72-10733 Air Conditioners, S/Ns-KT025145323R &

KT025146323R, (1) Hammond750 KVA Transformer, S/N-DB05J231, (1) Hammond

75 KVA Transformer, S/N-DAJST0DB822, Mounted on 10’3”W x 29’2”L Skid.

Rebuilt and tested.

(4) Shopbuilt 1’W x 9’L Electrical Suitcases

(6) Shopbuilt 3’7”W x 22’9”L Electrical Suitcases w/Grasshopper

Air Package :

(Note : Mounted on Generator Skids)

World Air RVK-40 Air Compressor, S/N-5483, p/b WEG 30 HP Electric Motor, Mounted

on No. 1 Generator Skid

Curtis Air Compressor, S/N-20601, p/b Baldor 20 HP Electric Motor,

S/N-206813260264, w/230-Gallon Air Receiver Tank, Mounted on No. 1 Generator Skid

BEL AIR 3D3HL Air Compressor, S/N-147266, p/b Baldor 20 HP Electric Motor,

S/N-20601260264, w/230-Gallon Air Receiver Tank, Mounted on No. 2 Generator Skid

Pump (Primary) :

LS NOI 3NB1300C(10P130 style) Triplex Mud Pump, S/N-205-002, 1300 HP, w/(3)

6-3/4” x 10” Forged Steel Fluid Ends, Quick-Change Valve Caps & Cylinder Heads,

LS NOI 5000 PSI Pulsation Dampener, S/N-4J28, Double Life 5” x 6” Centrifugal

Charging Pump, S/N-5218, p/b Emerson 50 HP Electric Motor, S/N-C0510190029,

5000 PSI, Pressure Gauge, Mounted on 9’8”W x 30’2”L Skid.

Pump Power :

(2) Apollo 752 DC Traction Motor, S/N-41160046, 1000 HP, w/Emerson AB34 10 HP

Electric Blower Assembly, S/N-YC10E1B

Apollo 752 DC Traction Motor, S/N-7539480, 1000 HP, w/Emerson AB34 10 HP Electric

Blower Assembly, S/N-YC10E1B

Pump (Standby)

LS NOI 3NB1300C (10P130 style)Triplex Mud Pump, S/N-204-030, 1300 HP, w/(3)

6-3/4” x 10” Forged Steel Fluid Ends, Quick-Change Valve Caps & Cylinder Heads, LS

NOI 5000 PSI Pulsation Dampener, S/N-4J4, Double Life 5” x 6” Centrifugal Charging

Pump, S/N-5219, p/b Emerson 50 HP Electric Motor, S/N-C0510190034, 5000 PSI,

Pressure Gauge, Mounted on 9’8”W x 30’2”L Skid.

Pump Power :

(2) Apollo 752 DC Traction Motor, S/N-7538070, 1000 HP, w/Emerson AB34 10 HP

Electric Blower Assembly, S/N-YC10E1B

Apollo 752 DC Traction Motor, S/N-7428792, 1000 HP, w/Emerson AB34 10 HP Electric

Blower Assembly, S/N-YC10E1B

Rotating Equipment :

MUD KING RT275 27-1/2” Rotary Table, S/N-27511, w/Split Master Bushings, p/b

Apollo 752 Traction Motor w/Emerson AB34 10 HP Blower Assembly - Rebuilt.

Mud King 450-Ton Swivel - Rebuilt

5-1/4” x 40’L Hex Kelly

Varco HD Kelly Drive Bushing

International tools kelly spinner - Rebuilt

TIW Upper Kelly Spinner

TIW Lower Kelly Spinner

Traveling Equipment :

Ideco 525-Ton Block/Hook Combination Rebuilt

2-3/4” x 132” Elevator Links

Well Control Equipment :

Hydril GK Type 13 5/8” 5000# Annular Blowout Preventer - Rebuilt

Schaffer LWS Type- 13-5/8” x 5000 PSI DOUBLE Blowout Preventer - Rebuilt

Choke Line: (1) 4-1/16” x 10M Gate Valve, (1) 4-1/16” x 5M HCR Valve

Kill Line: (2) 2-1/16” x 10M Gate Valves, (1) 2-1/16” x 5M Check Valve

CPCPB 40-32 5-Station Closing Unit, S/N-4635, w/(16) 11-Gallon Accumulator Bottles,

Triplex Pump, S/N-05556, p/b Baldor 20 HP Electric Motor, S/N-20502170516, (2) Air

Pumps, S/Ns-205902170516 & 205902170517, Gauges, 8’W x 8’2”L Skid. Pressure tested.

5 - Station remote closing unit, mounted in doghouse

5000 PSI Choke Manifold w/5-Way Cross, (2) 4-1/16” x 10M Gate Valves, (7) 2-1/16” x 10M

Gate Valves, (2) 2-1/16” x 10M Adjustable Chokes, Mounted on 8’W x 14’L Adjustable-Height

Skid.

Rig Houses :

Shopbuilt 7’9’W x 25’1”L Doghouse w/5’L Covered Porch, Knowledge Box, Bench Storage,

Cabinets, Lights, Skidded

Shopbuilt 10’2”W x 33’1”L Change House w/Round Top, Knowledge Box, (24) Lockers, Bench

Storage, Cabinets, Washer, Lights, Skidded

(2) Shopbuilt 8’W x 19’10”L Parts Houses, Each w/Round Top, Parts Bins, Skidded

Mud System :

Shopbuilt 10’W x 9’6”’H x 50’L 543-Barrel Suction Tank w/9’L Covered Porch, (3) Compartments,

(5) Grove Gear 7-1/2 HP Mud Agitators, S/Ns-801759310051, 8017513100 & 80175931105,

Each p/b Marathon 7-1/2 HP Electric Motor, S/Ns-BV74445, BV74457, BV74456, BV74448

& BV74443, Mud Hopper, Caustic Tank, Internal Plumbing, Flat Bottom, Top-Mounted Walkways,

Stairs, Safety Rails, Skidded

MCM 5” x 6” Centrifugal Mixing Pump, S/N-11945, p/b Baldor 50 HP Electric Motor,

S/N-C065180234

MCM 5” x 6” Centrifugal Mixing Pump, S/N-11288, p/b Baldor 50 HP Electric Motor,

S/N-C065180224

Shopbuilt 10’W x 9’6”’H x 50’L 543-Barrel Shaker Tank w/10’W x 9’L Covered Porch, (3) Compartments,

Grove Gear 7-1/2 HP Mud Agitator, S/N-80175931005, p/b Marathon 7-1/2 HP Electric Motor,

S/N-BV74454, Internal Plumbing, Flat Bottom, Top-Mounted Walkways, Stairs, Safety Rails, Skidded

MCM 5” x 6” Centrifugal Desilter Pump, S/N-11915, p/b Marathon 50 HP Electric Motor

MCM 5” x 6” Centrifugal Desander Pump, S/N-11945, p/b Baldor 50 HP Electric Motor,

S/N-C0508110044

Odrill/MCM Linear Motion Shale Shaker - New

OdrillL/MCM Linear Motion Shale Shaker

Double Life Desander, S/N-3159, w/(2) 10” Cones

Double Life Desilter, S/N-3158, w/(8) 2” Cones

Dreco “Deep Pit” Degasser, S/N-3295, p/b Baldor 5 HP Electric Motor

Shopbuilt 10’ W x 9’6”H x 50’ long Mixing Tank. Two 15 hp Agitators. High pressure guns. Pit levelers.

Dump gates. Three Dividers. Oilfield Three Runner skid.

Water / Fuel Tanks :

Shopbuilt 10’2”Dia x 42’3”L 500-Barrel Water Tank, Skidded - New

Baker SPD 2” x 3” Centrifugal Water Pump, S/N-2012, p/b Teco 25 HP Electric Motor, S/N-050501000,

Mounted on Generator Skid No. 3

BAKER 2” x 3” Centrifugal Water Pump, S/N-2017, p/b Teco 25 HP Electric Motor,

S/N-05134600909, Mounted on Generator Skid No. 3

Shopbuilt 8’Dia x 32’3”L 12,141-Gallon Fuel Tank w/(2) SIEMENS Fuel Transfer Pumps, Each p/b Teco 2 HP

Electric Motor, S/Ns-BQ0520600001 & BQ0520600002, w/4’L Covered Porch, Skidded

Murphy 5-Compartment Lubester w/Pumps, Hoses, Reels, Mounted on 6’W x 13’L Skid

Handling Tools :

Varco SSW-10 Pipe Spinners

Type DB 3-1/2” x 10 3/4” Rotary Tongs, S/N-10031M1399 - Rebuilt

5” 350-Ton Drill Pipe Elevators

5” Drill Pipe Slips

6-1/2” Drill Collars Slips

8” Drill Collar Slips

6-1/2” & 8” Safety Clamps

Juling XJF5-35 Air Hoist, S/N-0509-1, 10,000 Lb. Capacity

Juling XJF5-35 Air Hoist, S/N-0509-2, 10,000 Lb. Capacity

5” Mud Bucket

Instrumention :

Petron Weight Indicator, S/N-G1800 (NOTE: Located in Doghouse - Rebuilt

Totco Automatic Driller - Rebuilt

M&F Type D Mud Gauge, S/N-6773 - New

Auxiliary Equipment :

3-1/2” x 65’L Rotary Hose - New

3-1/2” x 12’L Vibrator Hose - New

3-1/2” x 18’L Vibrator Hose - New

Shopbuilt 5’W x 18”H x 60’L Catwalk, 2-Section, Steel Deck

(3) Sets of (6) 18”H x 28’L Shopbuilt Triangular Pipe Racks

Shopbuilt 8’W x 40’2”L Junk Box, Skidded

FIVE STAR Wireline Measuring Device, S/N-XCU081006N4, w/15,000’ of .092 Wireline - New.

1-3/8” Drill Line w/Ingersoll-Rand Air Tugger, S/N-SP051123032, Chain Driven. New drilling line

Rathole & Mousehole

Fluorescent, Mercury-Vapor & High-Pressure Sodium Rig Lights w/Wiring - All new wiring

Miscellaneous Spare Parts, Valves, Fire Extinguishers, Etc.

|  |

| |

|

Id: WR1129

Gus Pech GP-1300 Brat Series Drilling Rig - For Sale

Worldrigs ID: WR1129 Description :

Gus Pech GP-1300 Brat Series Drill Rig

Single Owner Unit and Delivered in 2003

Mounted On 2003 Sterling Truck 6x4

Cat Diesel Engine – PTO Driven

Rig Has 18,200 Hours

New Engine At 12,900 Hours – (5,300 Hours On Engine)

12" Tube Style Mast

Two-Way Cross Top Head Slide

Planetary Top Head Drive

Gp-1300 Hydrostatic Top Head Drive 0-65 Rpm@ 13,000 Ft Lbs.,

0-145 Rpm@ 5.828 Ft Lbs. Torque 24ft Stroke, Cable, Hydraulic Cylinder

Actuated Pulldown/Retract Drill System (Pulldown 18,412 Lbs./Retract: 24,537 Lbs.)

Bypass Circuit For Rapid Pulldown/Retract System

Pulldown/Holdback Feed Control System

Two Speed Retract

Dual Hydraulic Pump Drive System With Enlarged Gear Pumps For Increased Speed

Oil Cooling System

Standard Lighting (2)

Tower Tool Carrier For Transportation

4 Point Outriggers : 5ftx36"X3* Front Behind Cab Hosed Together

With One Control And 5"X30"X3" Rear

Operator Controls Including Tachometer, Key Ignition Switch,

And Gauges Pertinent To The Operation Of The Drill

Angle Drilling Lower Tower Supports

Operator Foot Stand

Hydraulic Slide Base

Hydraulic Lowering Brat E Style Foot Guide With Hydraulic Too!

Clamp (Enlarged To Handle 8-1/4" Id Augers)

Hydraulic Swing Around Jib With Hydraulic Extension

2.000# (First Layer) Gp Winch, With Large Dia. Drum, W/Headache Ball,

1/4" X 150ft Cable With Swivel Rook, on Jib

12.000# (First Layer) Pullmaster Winch with Rapid Reverse

1/2ft X 200ft Cable With Swive! Hook

Diedrich Sample Hammer System

Stationary Drill Rod Rack (10ft) With Hammer Holder For Nwj (150ft - 30 Rods)

Special 5ft Rod Rack Under 10ft Rod Rack For 20 AWJ Rods

Swing Around Auger Racks (2) Under Both Sides of Rig

Swing Around Auger Rack, Rear Mounted As Per Basil Rig

2-1/2" U-Joint Attachment With 2" Adapter

2 Sets Auger Guide Bushing (8-1/4" Id.)

Cotta Heavy Duty Transfer Case System

Location : North America

|  |

| |

|

Id: WR939

CME 55 Drilling Rig - For Sale

Worldrigs ID: WR939

Description :

1998 CME 55 Drill Rig - Serial: 287885

Length : 14ft / Width : 96" / Mast height : 30ft

Moyno Pump

Safety hammer

Cat Head

Slide base and wiggle tail

Cummins B3.9c 110 HP 4 Cylinder 3.9L Diesel Engine - Serial: 45680855

Hours : 12,632

Poly tank

Capacity : 940L

Mounted on a 1998 GMC C7500 Truck - VIN: 1GDM7H1C2WJ515925

Miles : 289,463 on odometer

Caterpillar 3126 Diesel 6 Cylinder 7.2L Diesel Engine

Eaton Fuller Manual 9 Speed Transmission

Suspension : Spring

Brakes : Air

GVWR : 33,000 lbs

Wheelbase : 190"

AC, Heat

Front : 11R22.5, Rear Duals, Ironman Tires

Location : USA

|  |

| |

|

|

|

Id: WR974

Taylor RT 5000M Trailer Mounted Drilling Rig - For Sale

Worldrigs ID: WR974

Description :

2007 Taylor RT 5000M Trailer Mounted Drill Rig

Complete RC Reverse Circulation Drilling Package

DSM 18” Table

3000ft Sandline Winch

Cat C15 Diesel Engine - rated 475 hp (low hours)

Cat TH-35 AutomaticTransmission

Hercules Dolly/Jeep tandem axial

Mud Tanks (2)

Western Rubber 6WC swivel and RC Kelly

40 ft trailer equipped with "doghouse" and 25 KVA generator

Jacks for drilling rig (qty. 2)

Drill pipe 7" x 30" x 6-5/8” Drilcox 51⁄2”ID (qty. 38)

Drill collars 9”od x 5-1⁄2” ID x 30ft x 6-5/8” Drilco MxF (qty. 7)

Drill collar extensions 9" W x 68" L (qty. 2)

Low Hours

Very Good to Excellent Condition per seller

Sub for bits 9" W x 36" L (double female)

Sub for bits 9" W x 26" L (double female)

Misc Sub lift for drill collars (qty. 4)

Slips for drill collar

Slips for drill pipe - Drill tongs (qty. 2)

Splitter box - Power tongs

8" Kelley hose 38 ft - Clipper weight scale

Price Reduced in February 2023

21,658.3 Hours on the digital gauge

Location : USA

|  |

| |

|

Id: WR633

850HP Super Single Drilling Rig for Sale

Worldrigs ID: WR633

General Description

Estimated Drilling Depth : 10,000 ft

Estimated Rig Move Loads : 22

Estimated Camp Move Loads : 4

Rated HP : 850

Mast

Height : 80.00 ft

Static Hook Load Capacity: 300,000 lbs

Mast Racking Capacity : N/A

Substructure

Style : Parallelogram

Height : 15.00 ft

Clear Height : 13.00 ft

Casing Capacity : 300,000 lbs

Maximum Setback Load (lbs.) : 300,000

No Drawworks

Top Drive / Power Swivel

Make : Tesco

Model : 250 HMI 475

Capacity : 250 Ton

Torque - Continuous : 21,000 ft-lb @ 56 rpm

No Swivel

No Rotary Table

Power Generation

Engines : 2 ea. Detroit Diesel Series 6063HV35

Generators : 2 ea. Stamford Power System HCI534DIL-0080E

SCR / VFD / DC/DC : Rack & Pinion Rig

Enhancements

Forklift : Caterpillar 930H

Iron Roughneck : Canrig Drilling Technology TM80-110-12-X-WX/PCS

Mud System

Mud Pumps : 2 ea Hong Hua HHF-1000

Power Rating : 1000 hp @ 140 spm

Reserve Mud Volume : 0 bbls

Pressure Rating : 5,000 psi

Active Mud Volume : 700 bbls

Shale Shakers : 2 ea. Derrick Corporation FLC 504

Desander : American Craftman 10" x 3 cones

Desilter : American Craftman 4" x 16 cones

Mud Cleaner : N/A

Centrifuge : N/A

Well Control

Choke Manifold : Quality Valve & Machine Works Inc., 3 1/8" 5,000 psi

BOP Closing Unit : Burnsco, 6 Station 3,000 psi

|  |

| |

|

Id: WR945

Ingersoll-Rand T3W Drilling Rig - For Sale

Worldrigs ID: WR945

Description :

1990 Ingersoll-Rand T3W Drill Rig

Cummins 855 Diesel Deck Engine (200+ hours since rebuilt)

IR 825 cfm / 350 psi air compressor

(6) of 20ft x 4-1/2" drill pipe included

Myers water injection

Hammer lubricator

Hydraulic Leveling Jacks

Mounted on a Ford L9000 Truck

Cummins L10 Diesel Engine - rated 300 horsepower

Location : USA

|  |

| |

|

|

|

Id: WR958

Atlas Copco CM-780D Blast Hole Drilling Rig - For Sale

Worldrigs ID: WR958

Description :

2007 Atlas Copco CM-780D Blast Hole Drill

Crawler Mounted

Caterpillar C13 Diesel Engine

S/N: G78322D

IR HR2 865 CFM / 350 PSI Air Compressor

Bean 8 GPM Water injection Pump

Hammer lubricator

Thread Greaser

Enclosed Cab

A/C & Heater

Telescoping Boom

Rod Changer

13-1/2" Track Shoes

Set up for (4”O.D. x 13.1ft) drill pipe 21/2Z thread

Service records available for 2018/2019

Location : USA

|  |

| |

|

Id: WR942

Bucyrus Erie 22W Series II Cable Tool Rig - For Sale

Worldrigs ID: WR942 Description :

Bucyrus Erie 22W Series II Cable Tool Rig

Mounted on 1989 International S1800

4x4 Truck

New Cable

New Drill Line

Basic Tooling Included (6" & 8" Bits)

Location : USA

|  |

| |

|

Id: WR1084

Sandvik M5 Drilling Rig - For Sale

Worldrigs ID: WR1084

Description :

2007 Sandvik M5 Drill Rig

1075 cfm / 350 psi Air Compressor

12,000lb Winch

Setup For 4.5" Rods

8000+ hours

Cummins 565 Diesel Engine

New Transfer Case

|  |

| |

|

|

|

Id: WR955

Mobile B-53 Drilling Rig - For Sale

Worldrigs ID: WR955 Description :

1990s Mobile B-53 Drill Rig

Moyno progressive cavity pump

SPT Auto Hammer

Rod clamp and more as can be seen in pictures

Numerous augers and other tooling included

Drill showing 4031 hours, appears to be ready to go to work today

Mounted on Ford F800 diesel truck

20560 miles on gauge

Location : USA

|  |

| |

|

Id: WR990

Schramm T64HB Drilling Rig - For Sale

Worldrigs ID: WR990

Description :

1978 Schramm T64HB Drill Rig - S/N: T64HB-1186

Long Tower with jib boom

(9) 4-1/2" x 20ft drill rods included

Rod rack

Detroit Diesel Deck Engine

Schramm 425 cfm / 250 psi air compressor

Cat water injection pump

(3) leveling jacks

Table bushings

Drill collar and steel tooth tri-cone included

Mounted on a GMC 7500 Truck - VIN# TJV738V566193

13 Speed Transmission

6 Cylinder Detroit Diesel Engine

10.00-20 Tires

Shows 60,940 Miles

Note: Truck runs and drives when tested last

Location : USA

|  |

| |

|

Id: WR1020

Drilling Rig for Sale-1.webp)  Drilling Rig for Sale-1.webp) Derex 1340-14 DR (Dual Rotary) Drilling Rig - For Sale

Worldrigs ID: WR1020

Description :

Derex 1340-14 DR (Dual Rotary) Drill Rig

Truck

Peterbilt 567

Paccar 11 Litre

Allison 6 speed automatic

Air ride

Transfer Case

Namco (oilfield quality)

Safe Shift

Hydraulic System

Bosch Rexroth plus gear pump

Top Head

Variable torque and RPM with 2” thru-hole

0-125 rpm @ 3,500-lbf

Lower drive

Variable torque and RPM with 10” thru-hole

0-23 rpm @ 20,000-lbf

Diverter

Simple seal design with 4” NPT discharge

to control cuttings.

Derrick & Feed System

13ft top head stroke (handles 10ft x 3" OD drill pipe)

40,000-lbs pullback

20,000-lbs pulldown

100 FPM

Derrick slide/ dump

4ft Derrick slide for angles up to 45°

Main Winch

Manual jib

2,500 lb.

Remote on helpers side for winch

Control Panel

Straight hydraulic controls (no electrics to fail)

Marine grade electric switches (for lights)

Murphy engine monitor display

Twin platforms

Leveling Jacks

Four 36” stroke independently controlled

Night Lights

6 LED night lights

Toolboxes

30”x 18” x 18”

Overall Dimensions

Length: 24ft 11”

Width: 8ft 6”

Derrick up height: 24ft 6” – 28ft 6” with Derrick slide

Derrick down height: 11ft

Water Injection

9 gpm FMC injection pump

Gross Weight

34,000lbs - 36,000lbs

Casing

Diameter 4", 5" & 6" (with 8" & 10" option for surface casing)

Pre-Order Drill from EWDAdditional Options

4 – 6 Month Leadtime from Date Ordered

Sand Line Winch

1,500ft sand line

Mud Pump

3x2x13 centrifugal 300 gpm/300 psi

Centerline piston 150 gpm/600 psi

Air Compressor Options

Vanair / Sullair 600cfm / 250psi @ 1,800rpm

Vanair / Sullair 733cfm / 150psi @ 2,200 rpm

Line Oiler

Many oilers available

Water InjectionDrill Pipe Packages

18 gpm FMC injection pump

Wire Feeder and Box

Hydraulic or Gas Welders

Location : USA

|  |

| |

|

|

|

Id: WR1088

Mobile B61 Drilling Rig - for Sale

Worldrigs ID: WR1088

Description :

Mobile B61 Drill Rig - S/N: 620237

Tulsa Winch

Moyno-type pump

King Swivel

Hydraulic Spool Valve Controls

Drilling Capacities :

Rotary Drilling with 2-5/8” diameter drill rod…… 1350 ft. (410 m)

(new drill rod can be purchased at an additional cost)

Core Drilling with AW size tools or AQ wire line… 2250 ft. (685 m).

Core Drilling with NW size tools or NQ wire line… 1350 ft. (410 m).

Continuous Flight-Auger Diameter Range…... up to 14” (355 mm).

Max. Depth with 6” Dia. (152.4 mm) Augers. 360 ft. (110 m).

Max. Depth with 8” Dia. (203.2 mm) Augers. 250 ft. (76.2m).

Note: Drilling Capacities are based on maximum depths obtained in

actual field test and will vary with local subsurface conditions.

Mounted on an International Loadstar truck

Gas engine

Winch on front

Showing 3865 miles

Leveling Jacks

Location : USA

|  |

| |

|

Id: WR468

ZJ-40 Drilling Rig for sale

Worldrigs ID: WR468 Derrick

JJ22538 mast with guylines, hydraulic raising and telescoping, max. capacity 2250kN, windproof capacity with full setback, without hook load 110km/h, mast height 38m

14 X 8E Carrier Vehicle,drive type 14X8, max. speed(limited) 45km/h, climbing gradient 26%, min. Ground clearance 311mm, steering radius 19,5m

Hydraulic cathead cylinder

Hidraulic outrigger

Mast Raising and telescoping cylinders

Drill pipe Set Back Area (Racking platform capacity: 10 setbacks 7”DC, 4000m 4 ½”DP or 3200m 5” DP

Drillfloor in derrick area 7,4m X 7,4m

Monkey Board

Derrick lighting system

Hydraulic cathead cylinder

Stairways to rigfloor

Hand railings

Substructure

Substructure model ZZT 225D, max. load 2250kN, working height 6m, structure Parallelogram, working space below rotary beam 4,9m

Catwalk

Pipe Racks

Crown block model TC225, max. load 2250kN

Hook Block model YG225, max. load 2250kN

Swivel SL 225, working load 0f main bearing 1500KN(100r/min), max. work pressure 35MPa

Main oil pump, discharge capacity 208L/min, system pressure 21MPa/14MPa

TQ340-35 Casing Power Tong , Capacity 4 ½” – 13 3/8”

ZQ203-100 Drill Pipe Power Tong, 3 ½” – 5”

YZB-120 Hydraulic Power Station, Rated working pressure 16MPa

Pneumatic system, rated pressure 0,85MPa

Standpipe Manifold

Mud Valve Z23Y-35, 100mm - 5000psi

Standpipe 4 ½”

Rotary jumper hose (bottom standpipe)

Rotary Hose

Upper Kelly Valve

Kelly 5 1/4" Hexagonal

Kelly drive bushing - 5 1/4"

Lower Kelly Valve

Transmission box model Allison S6610HR, max. net input power 850HP, max. input rotary speed 2500r/min, max. net input torque 3118N.m

Compounding box model BJX260B, max. input rotary speed 2500r/min, max. output torque 26000N.m

Drawworks model JC28/11D, Main drum fast line pull 280KN

CAT C18 Diesel Engine, Power 630HP/2100r/min

Auxiliary Brake model WCB236, brake power 970HP, brake torque 66611Nm, circulating water pressure 40 psi

Drill Line – 1 1/4" diameter

Drill Line Spool

Drillers Console

Rotary Table - 27 1/2", model ZP275, max. Rotary speed 250rpm, max. Net load 4500KN, max. Torque 27kN.m

Rotary drive box, model ZX140B, max input rotary speed 2100r/min, max. input torque 14000N.m, Clutch model Axial thrust disk ATD318H

Masterbushing

Hydraulic winch model YJ3C, max. hoisting capacity 30KN

Hydraulic winch model YJ5B, max. hoisting capacity 50KN

BOP Control

B.O.P. Closing Unit

Remote Control Panel

13 5/8" 5000 PSI Annular BOP

B.O.P. 13 5/8", double studded complete with 2" side outlets (double ram - blind/pipe rams)

associated spools and DSA for BOP and Wellhead connections

Mud-Gas Separator

Choke Manifold 5000psi

BOP control hoses

Mud Treatment Package

ZG-58,4 Sand Control Tank (Shaker tank) with staircase

Shale Shaker Model QZS 703 El. motor 1.72KW 1400RPM x 2

Vacuum Degasser Model ZCQ 300, El. motor 3KW 1470 r/min, El. motor 4KW 1435 r/min

FG-49,4 Cycle Tank

Model 200SB 240-40 Sentrifugal Sand Pump, Rate 240m3/h, Inlet Diameter-200mm, Outlet Diameter-150mm, El. motor 55KW, 1480 r/min (For solids control system)

Desander Model LCS 250 x 2 with shale shaker, vibration el. motor 0.8KW 1410 r/min

Desilter Model CNQ 100 x 10, with shale shaker, vibration el. motor 0.75KW 1400 r/min

Centrifuge Model LW 450x842-N, El. motor 5.5KW 1440 r/min, El. motor 22KW 1470 r/min

FG-54,6 Cycle Tank (suction tank) with staircase

Agitator Model WNJ 11, El. motor 11KW 1460 r/min

Model 200SB 240-40 Sentrifugal Sand Pump, Rate 240m3/h, Inlet Diameter-200mm, Outlet Diameter-150mm, El. motor 55KW, 1480 r/min (For mud hoppers)

Mud Hopper

Mudgun

Water tank - 500bbl Capacity, with water pump

Mud Pumps

Mud Pump F-1000, triplex, rated stroke length 10”, Maximum WP 5000 psi

Suction manifold – 12”

Charging pump, centrifugal, model SB200x150-310, lift 25m, flow 180m3/h, el. Motor 37KW, 1490r/min

Pump engine, model G12V190PZL-3

Generator Package

MSS System, model WB ZJ40-3

Power supply system FKS-V400

Diesel-Generator Set, model FKS-V400, Diesel engine TAD 1345GE, power 400KW, 400V, 1500rpm, 50Hz

Air supply system

Electric Control Panel

SULLAIR 3000 Compressors, max. W.P 210psi, max. temp. 2350F with JYL 50F Refrigerated Compressed Air Dryers

Air Receiver 3m3

FUEL SYSTEM

Fuel Supply System

Fuel Tank – 50 m3 with fuel pump

Rigsite Accommodation

Container 20ft – Rig manager

5 Man bunkhouse units - container type caravan.

2 Man bunkhouse units – container type caravan with communal shower and toilet facilities.

8 man bunkhouse units – container type caravan with communal shower and toilet facilities.

Container 20ft for kitchen personal.

Container 20ft for Doctor.

Kitchen Galley -fully equipped kitchen and communal eating facilities

Storage container 20ft

Container mud lab.

|  |

| |

|

Id: WR1029

Drilling Rig for Sale-1.webp) Atlas Copco T4BH (Blasthole) Drilling Rig - For Sale

Worldrigs ID: WR1029

Description :

2010 Atlas Copco T4BH (Blasthole) Drill Rig - S/N: 9089

Cummins QSK19 Diesel Deck Engine - rated 755HP & 1800 RPM (11.3 Hours on Meter)

IR HR2.5 1250 cfm / 350 psi Air Compressor

2 Motor Spur Gear Power Head

37,500 LBS of Pullback

5 Rod Carousel Set Up for (3) 7” Drill Pipe

Hammer Lubrication

2 Piston Bean Water Injection

2010 Mounted on a CCC (Crane Carrier Company) Truck - VIN#1CYDCV580AT049672

Caterpillar C13 Diesel Engine - rated 325 HP

Jake Brakes

8LL Speed Transmission

Note: Can be converted to T4W or T4W DH for water well drilling for an extra cost

Note: Bill of sale only

Location : USA

|  |

| |

|

|

|

Id: WR1081

Schramm T555 Drilling Rig - For Sale

Worldrigs ID: WR1081

Description :

2003 Schramm T555 Drill Rig - S/N: J109-0101

Caterpillar C15 Diesel Deck Engine

Sullair 1050 cfm / 350 psi Air Compressor

Less Than 2,000 Hour Since Rebuilt

9,653 Hours On gauge

Main Pump Just Rebuilt

6 Rod Carousel Inside Cable Feed

Basic Rod Handling

Table Bushings & basic tooling Included

No Pipe Included but 500 ft of Drill Pipe (20ft x 4-1/2" x 3-1/2" API)

Available at an extra cost

Mounted On A Sterling Truck

CAT Diesel Engine

19,206 miles on gauge

Location : USA

|  |

| |

|

Id: WR914

Gus Pech KH-48 Super George Drilling Rig - For Sale

Worldrigs ID: WR914

Description :

Gus Pech KH-48 Super George Drill Rig

Tandem Axle

Day Cab

Mack Diesel Engine

Camel Back Suspension

Double Pump Unit

Tilt Mast

SN: 41KSG48A1076

Maxitorque 13 Speed Transmission

Mounted on a 1993 Mack RB688S Truck

Average Tires

4-Point Stabilizers

Location : USA

|  |

| |

|

Id: WR951

Ingersoll-Rand TH60 Drilling Rig - For Sale

Worldrigs ID: WR951

Description :

1987 Ingersoll-Rand TH60 Drill Rig

Mounted on a GMC General Truck

Detroit 8V92 Silver Series Diesel Engine - rated 475 HP

Note: 3000 hours since rebuild with list below

8100 original frame hours

45,000 miles on chassis

13 speed road ranger transmission

IR 825 cfm / 350 psi air compressor

28,000 pull back

18k main winch

Auxiliary sand line winch

Hammer oiler

Single rod loader-murphys plug

Machine recently outfitted with swinging- telescoping jib crane

with helper side controls

Rebuilt hydraulic jacks

Rebuilt main feed cylinder

Rebuilt fan motor

Rebuilt water injection pump

Rebuilt and reinforced rod box

Rebuilt retract cylinder

Newer air controls at drillers panel

All newer wheels and tires steering and traction-no recaps

All newer brakes all the way around

Newly built underbody heavy duty steel tool box for table

bushings-drill bits-wrenches etc.

Dual 120 gallon aluminum fuel tanks

Newer batteries

Miller 225 welder mounted on deck with leads ran to back very low hours on welder

Racks for water hoses

Per Driller : Machine is drilling daily

Stored inside always unless on a job for past 20 years

Comes with standard table bushings and wrenches

Murphys lifting plug

400 ft 4 1/2" drill rod

Carousel holds 140 ft remainder in rod box

Undercarriage and frame in excellent condition with no rust-rot

Interior of cab is very nice, all working lights and gauges vacuumed and

cleaned weekly

Location : USA

|  |

| |

|

|

|

Id: WR1073

Schramm T660-H Drilling Rig - For Sale

Worldrigs ID: WR1073

Description :

1989 Schramm T660-H Drill Rig

Cummins 855 Diesel Deck Engine

GHH 900 cfm / 350 psi Air Compressor

Set up for 280 feet of 4.5” drill rods with 4 Rod Lazy Susan carousel

10 Rod rack on the side of the tower

30 ft head travel

Foremost floating sub adapter

Water injection pump

hammer oilier

400 Ft of drill pipe included

Mounted on a 2009 Mack Granite Truck with

485 HP Diesel Engine

18 speed transmission

It has 74,523 km (45,830 miles)

Location : Canada, North America

|  |

| |

|

Id: WR1040

Ingersoll-Rand T4BH Drilling Rig - For Sale

Worldrigs ID: WR1040 Description :

1999 Ingersoll-Rand T4BH Drill Rig - S/N: 6340

Note: set up for BH (blasthole drilling)

New IR 1050 cfm / 350 psi Air Compressor (needs to be installed at EWD)

Cummins QSK19 diesel deck engine - 3,500 hours since rebuilt

2 motor Spur gear head

37,500 LBS of pullback

2 piston Water injection pump

New gearbox, new cooler, rebuilt pumps and much more in 2022

6 drill pipe (4-1/2"x 25 ft x 3-1/2")

Rear operators cab

Mounted on CCC (Crane Carrier Company) Truck

Cummins L10 diesel engine

Note: Can be converted to T4W or T4W DH for water well drilling)

Location : USA

|  |

| |

|

Id: WR815

Alta 1500 HP AC/VFD Drilling Rig for sale

Worldrigs ID: WR815

Mast

Clear Height : 142’

Max. Static Hook Load (12 Lines) : 800,000 lbs

Max. Wind Capacity : 75 knots

Substructure

Floor Height : 25’

Clear Height : 20’-6”

Rotary Capacity : 800,000 lbs

Setback Capacity : 600,000 lbs

Hole Opening : 37-1/2”

Top Drive

Max. Static Hook Load Rating : 500 tons

Max. Speed : 265 rpm

Max. Intermittent Torque : 71,000 ft-lbs

Max. Continuous Torque : 51,400 ft-lbs

Pressure Rating : 7,500 psi

Drawworks

Rated Capacity : 1500 hp

Max. Capacity (12 lines) : 800,000 lbs

Drum Groove : 1-3/8”

Mud Pumps

Input Horsepower Rating : 2,200 hp

Maximum Pump SPM : 120 rpm

Maximum Liner Size : 9”

Minimum Liner Size : 5”

Stroke : 14

Power Generation

Generator Power : 1350 kW @ 1200 rpm

Engine Power : 1476 HP @ 1200 rpm

|  |

| |

|

|

|

Id: WR1017

Drilling Rig for Sale-1.webp)  Drilling Rig for Sale-1.webp) Derex 1340-16 DR (Dual Rotary) Drilling Rig - For Sale

Worldrigs ID: WR1017

Description :

Derex 1340-16 DR (Dual Rotary) Drill Rig

Truck

Peterbilt 520

Paccar 13 Litre.

Allison 6 speed automatic

Air ride

Transfer Case

Namco (oilfield quality)

Safe Shift

Hydraulic System

Bosch Rexroth plus gear pump

Top Head

Variable torque and RPM with 2” thru-hole

0-125 rpm @ 3,500-lbf

Lower drive

Variable torque and RPM with 10” thru-hole

0-23 rpm @ 20,000-lbf

Diverter

Simple seal design with 4” NPT discharge

to control cuttings.

Derrick & Feed System

13ft top head stroke (handles 10ft x 3" OD drill pipe)

40,000-lbs pullback

20,000-lbs pulldown

100 FPM

Derrick slide/ dump

4ft Derrick slide for angles up to 45°

Main Winch

Manual jib

2,500 lb.

Remote on helpers side for winch

Control Panel

Straight hydraulic controls (no electrics to fail)

Marine grade electric switches (for lights)

Murphy engine monitor display

Twin platforms

Leveling Jacks

Four 36” stroke independently controlled

Night Lights

6 LED night lights

Toolboxes

30”x 18” x 18”

Overall Dimensions

Length: 24ft 11”

Width: 8ft 6”

Derrick up height: 24ft 6” – 28ft 6” with Derrick slide

Derrick down height: 11ft

Water Injection

9-GPM FMC injection pump

Gross Weight

36,000lbs - 38,000lbs

Casing

Diameter 4", 5" & 6" (with 8" & 10" option for surface casing)

Pre-Order Drill from EWDAdditional Options

4 – 6 Month Leadtime from Date Ordered

Sand Line Winch

1,500ft sand line

Mud Pump

3x2x13 centrifugal 300 gpm/300 psi

Centerline piston 150 gpm/600 psi

Air Compressor

Vanair / Sullair 900cfm / 350psi

Line Oiler

Many oilers available

Water InjectionDrill Pipe Packages

18 gpm FMC injection pump

Wire Feeder and Box

Hydraulic or Gas Welders

Location : USA

|  |

| |

|

Id: 9000-487

Service King 1000 HP Drilling Rig for Sale

Worldrigs ID: WR703

Description :

Crown, (4) Sheave McKissick, 1 ¼”,

Date : 1/ 2012,

SHL : 450,000#

S/N: DK504, Cluster Model : 744-1, 1 1/8” Line, 36” Sheaves,

Fast Line Model : 741-1, 1 1/8” Line, 42”, 40 Tons,

Sand Line Model : 741-1, 1.12” Line, 30” Sheave, 40 Tons

Dead Line Anchor Model : 741-1, 1 1/8” Line, 30” Sheave

Carrier, (5) Axel / Trailer Mount, Model 1000,

SK#: 395T, Gross Weight:, 177,900 Lbs.,

Date: 3/2012, VIN: 1S90TDD85CL976333, (1) Sand Line Reel

(1) Electric Drive Hydraulic Pump,

(2) Oil Saver Hydraulic Filters

Engine # 1, Detroit 2010 Model, 14.0 Litre,

Allison Transmission, S/N: 06R1049132

Engine # 2, Detroit 2010 Model, 14.0 Litre,

Allison Transmission, S/N: 06R1049335

(1) Hydraulic Tank – 350 Gallons

Drawworks, Model:

46 x 10, S/N: DW 2387, Transmission,

Model: 1000, S/N: 5962350

S/N: 5962688, Power Drive Gear Box: 2.47 x 1,

Dual Actuated Air Band Brake, Hydraulic Drum Brake,

Air Actuated Crown Saver, (2) Hydraulic Cat

Heads – Make Brake, (1) Drillers Console

Mast, Model:

117ft, SHL 450,000#, S/N: DK 504,

(3) Hydraulic Raising Cylinders

Built in Top Drive Torque Track, Kelly Hose, Stand Pipe 5000 PSI

with 5000 PSI Type D MSF Mud Gauge S/N: 41814, (3) 5000 PSI

Oteco Shut Off Vales, (2) 250 Ton Bails – 79” Long,

Finger Board – (22) Fingers, (1) Sentry Block / Hook

Combo Model SI-BH-250, 36” Sheave Size Line 1 ¼”, S/N: 07054,

Date: 2007, (2) Air Hoist Lines, Fully Rigged for Safety Cable,

Number of Raising Cylinders = Number of Extensions

Mud Pits :

(2) Pit System – 950 BBL

Shaker Pit (2) Compartments, (2) Swaco Mongoose Shakers,

S/N: PF 2664, S/N: PF 2663, (1) Mongoose Mud Cleaner with

Desander Model: 2-12, S/N: 21963, S/N: 4500732 / Desilter,

Model: 6T4, S/N: 23043, (1) 5 Star 6 x 5 x 14 Cent Pump p/b

50 HP Electric motor

Suction Pit, Full Set of Pit Lights, (2) Caustic Barrels,

(4) 10 HP Agitators (4) Compartments, (2) Prime Mud Movers –

Mission Magnum 6 x 5 x 14 ea p/b 50 HP elec motors

Water Tank :

500 BBL, (2) 25HP Mission Water Transfer Pumps x 4RS,

(2) Compartment Chemical Pit

Gas Buster, Swaco, Model: 2011, 4ft x 10ft, 6” Outlets,

6” Inlets, S/N: MGS-M-118 Skidded

Choke Manifold, (6) 4 x 5M, MGV – HECI, (1) 2 x 5M, MGV – HECI,

(1) 2 x 5M Manual Choke – HECI, 3 Way Watermelon

Pill Pit, (1) Five Star 6 x 5 x 14 Cent Pump p/b 50HP

elec motor w/(1) Hopper

Mud Pump #1, SLF 1300, Engine: Cat 399B PCTA, Date: 12/23/2011,

S/N: 35B06278 Torque Converter, Oil Works, Model: C-300-100,

Type E, S/N: 1600, Five Star Charge Pump, 6 x 5 x 14 p/b 50HP

Electric Motor –, (1) 5000PSI Pulsation Dampener, (1) 5000PSI

Emergency Pop Off – Odrill, (2) 5000PSI Gate Valve - Oteco

(3) SLF 1300 Modules

(1) Mud Pump Center Skid with Frogs, Miscellaneous Basket,

Rig Mats (Table Mats)

Mud Pump #2, SLF 1300, S/N: KMI 01, Engine: Cat 399 PCTA,

Date: 05/ 2011, S/N: 35B4092, Torque Converter, Oil Works,

Model: C-300-100, Type E, S/N: 1600, Five Star Charge Pump,

6 x 5 x 14 p/b 50HP Electric Motor –, (1) 5000PSI Pulsation

Dampener, (1) 5000PSI Emergency Pop Off – Odrill, (2) 5000PSI

Gate Valve – Oteco (3) SLF 1300 Modules

(1) Top Dog House with Tools, (2) BJ Elevators, (2) Tongs,

(3) Slips, (2) Drill Pipe Slips, (4) Mud Wipers, (4) Sets

of Pit Stairs, Spare Tong Heads, (1) Hydraulic Accumulator

Suit Case

BOPs :

(1) 11” 5M Annular – Hydril GK

(1) 11” 5M Double – Shaffer Style

(1) 11ft 5M Mud Cross with Wing Valves

Top Drive :

Venture Tech 250 T w/ (1) Top Drive Service Loop, (1) Bottom

Half for Top Drive Torque Track, Hydraulic Top Drive House p/b

(2) Detroit 60 Series (14.0 Litre), has “Dan Voss” Hydraulic

Drive Pump System – (2) Pumps ea (4) Outlets ea, (1) Bug Blower

(1) Basket with (6) Crossover Subs

Junk Basket, Floor Hand Rails, Flow Line Skid with hoses,

(2) Oteco Valves, Miscellaneous Flow Line Plumbing,

(1) 4ft x 20ft V Door, (3) Saver Subs, (1) Crossover Sub

Accumulator :

Advanced Pressure Inc., (12) Bottles, 5 Station, 3000PSI System,

S/N: 11871, (2) 55 to 1 Air Pumps, (8) Steel Flex Accumulator

Lines, (1) Pressure Washer Power Swivel, Venture Tech,

Model: XK 250 Ton

Generator House :

Genset # 1, Engine: 12V 2000, Generator: Kohler – 450KW,

Model: Power Systems 600

Genset # 2, Engine: 12V 2000, Generator: Kohler – 450KW,

Model: Power Systems 600

(1) Screw Compressor – Gardner Denver, Electra Saver,

Model: EBE 990, S/N: S334319

Mud Boat – Main Section, 60ft Long x 10ft Wide (4) 12” Beams

Mud Boat – Extension, 17ft 3” Long x 11ft Wide

Substructure, 35ft Long x 11ft Wide

Rotary Table, Sentry – 20.5”, Date: 2007, S/N: 074102

(1) Rotary Angle Gear Box

(1) 40ft Parts House with Divider

(1) Wire Line 15,000 x .092 – Five Star

Consumables

Camp Transformer – 6 Outlets

Location : USA

|  |

| |

|

Id: WR1039

Mobile Drill B-57 Auger / Coring Drilling Rig - For Sale

Worldrigs ID: WR1039

Description :

Mobile Drill B-57 Auger / Coring Drill Rig - Serial : 90091

Cummins 4 Cylinder Deck Diesel Engine

Mounted on a 1990 Ford F800 truck - VIN : 1FDXK84A6LVA47983

Miles : 106,812 on odometer

Ford 6-cylinder Diesel Engine Displacement : 7.8L

Manual 10 Speed Transmission

Axles : Tandem

Lift axle

Pusher axle

GVWR : 30,000

Features : Bed/drill

Bean Triplex Piston pump

Saftey hammer

Tires Size : 11R22.5

Location : USA

|  |

| |

|

|

|

Id: WR1076

Atlas Copco Boomer L2C Drilling Rig - For Sale

Worldrigs ID: WR1076

Description :

Atlas Copco Boomer L2C Drill Rig

Diesel Motor 2013 L042V Deutz

Transmission Dana Spicer Series AVO11D254E

Front Differential Dana Spicer Series AVO11D214E

Rear Differential Dana Spicer Series NBEA378017

Last registry of hours : August 2018

Hours on the Diesel Motor : 1,017 Hours

Arm 1 = 154 Hours on Electric Motor

Arm 2 = 157 Hours on Electric Motor

Location : Northern Mexico

|  |

| |

|

Id: WR1030

Drilling Rig for Sale-1.webp) Atlas Copco T4BH (Blasthole) Drilling Rig - For Sale

Worldrigs ID: WR1030

Description :

2009 Atlas Copco T4BH (Blasthole) Drill Rig - S/N: 8887

Cummins QSK19 Diesel Deck Engine - rated 755HP & 1800 RPM

IR HR2.5 1250 cfm / 350 psi Air Compressor

Hour meter shows 3157.3 Hours

2 Motor Spur Gear Power Head with Foremost float sub

37,500 Lbs of Pullback

5 Rod Carousel set up for (3) 7” drill pipe

Hammer lubrication

2 Piston Bean water injection

2009 Mounted on CCC (Crane Carrier Company) Truck - VIN#1CYDCV58X9T048815

Caterpillar C13 Diesel Engine - rated 325 HP

Jake brakes

8LL Speed Transmission

Note: Can be converted to T4W or T4W DH for water well drilling for an extra cost

Location : USA

|  |

| |

|

Id: WR625

850HP Trailer Mounted Rack & Pinion Rig for sale

Worldrigs ID: WR625 General Description

Estimated Drilling Depth : 10,000 ft

Estimated Rig Move Loads : 22

Estimated Camp Move Loads : 4

Rated HP : 850

Mast

Height : 80.00 ft

Static Hook Load Capacity: 300,000 lbs

Mast Racking Capacity : N/A

Substructure

Style : Parallelogram

Height : 14.00 ft

Clear Height : 11.00 ft

Casing Capacity : 300,000 lbs

Maximum Setback Load (lbs.) : 300,000

No Drawworks

Top Drive / Power Swivel

Make : Tesco

Model : 250 HMI 475

Capacity : 250 Ton

Torque - Continuous : 21,000 ft-lb @ 56 rpm

No Swivel

Rotary Table

Power Generation

Engines : 1 ea. Detroit Diesel Series 6063HV35

Generators : 2 ea. Stamford Power System HCI534DIL

SCR / VFD / DC/DC : Rack & Pinion Rig

Enhancements

Forklift : Caterpillar 930H

Iron Roughneck : Canrig Drilling Technology TM80-110-12-X-WX/PCS

Power Slip Frame : TTS Sense 83415-04

Mud System

Mud Pumps : 2 ea Hong Hua HHF-1000

Power Rating : 1000 hp @ 140 spm

Reserve Mud Volume : 0 bbls

Pressure Rating : 5,000 psi

Active Mud Volume : 700 bbls

Shale Shakers : 2 ea. Derrick Corporation FLC 504

Desander : N/A

Desilter : N/A

Mud Cleaner : N/A

Centrifuge : N/A

Well Control

Annular : 11" 5,000 psi, Townsend, Type 90

Double Ram :

11" 5,000 psi, Jiangsu, 2FZ28-35

11" 5,000 psi, Townsend, Type 82

Choke Manifold : Quality Valve and Machine Works Inc, 3 1/8" 5,000 psi

BOP Closing Unit : Burnsco, 6 Station 3,000 psi

|  |

| |

|

|

|

Id: WR632

Trailer Mounted Rack & Pinion, Super Single Rig

Worldrigs ID: WR632

General Description

Estimated Drilling Depth : 10,000 ft

Estimated Rig Move Loads : 22

Estimated Camp Move Loads : 4

Rated HP : 850

Mast

Height : 80.00 ft

Static Hook Load Capacity: 300,000 lbs

Mast Racking Capacity : N/A

Substructure

Style : Parallelogram

Height : 14.00 ft

Clear Height : 11.00 ft

Casing Capacity : 300,000 lbs

Maximum Setback Load (lbs.) : 300,000

No Drawworks

Top Drive / Power Swivel

Make : Tesco

Model : 250 HMI 475

Capacity : 250 Ton

Torque - Continuous : 21,000 ft-lb @ 56 rpm

No Swivel

No Rotary Table

Power Generation

Engines : 2 ea. Detroit Diesel Series 6063HV35

Generators : 2 ea. Stamford Power System HCI534DIL

SCR / VFD / DC/DC : Rack & Pinion Rig

Enhancements

Forklift : Caterpillar 930H

Iron Roughneck : Canrig Drilling Technology TM80-110-12-X-WX/PCS

Power Slip Frame : TTS Sense 83415-04

Mud System

Mud Pumps : 2 ea Hong Hua HHF-1000

Power Rating : 1000 hp @ 140 spm

Reserve Mud Volume : 0 bbls

Pressure Rating : 5,000 psi

Active Mud Volume : 700 bbls

Shale Shakers : 2 ea. Derrick Corporation FLC 504

Desander : American Craftman 10" x 3 cones

Desilter : American Craftman 4" x 16 cones

Mud Cleaner : N/A

Centrifuge : N/A

Well Control

Double Ram : 11" 5,000 psi, Townsend, Type 82

Choke Manifold : Quality Valve & Machine Works Inc., 3 1/8" 5,000 psi

BOP Closing Unit : Burnsco, 6 Station 3,000 psi

|  |

| |

|

Id: WR635

Rack & Pinion, Super Single Drilling Rig for sale

Worldrigs ID: WR635 General Description

Estimated Drilling Depth : 10,000 ft

Estimated Rig Move Loads : 22

Estimated Camp Move Loads : 4

Rated HP : 850

Mast

Height : 80.00 ft

Static Hook Load Capacity: 300,000 lbs

Mast Racking Capacity : N/A

Substructure

Style : Parallelogram

Height : 14.00 ft

Clear Height : 11.00 ft

Casing Capacity : 300,000 lbs

Maximum Setback Load (lbs.) : 300,000

No Drawworks

Top Drive / Power Swivel

Make : Tesco

Model : 250 HMI 475

Capacity : 250 Ton

Torque - Continuous : 21,000 ft-lb @ 56 rpm

No Swivel

No Rotary Table

Power Generation

Engines : 3 ea. Detroit Diesel Series 6063HV35

Generators : 3 ea. Stamford Power System HCI534D

SCR / VFD / DC/DC : Rack & Pinion Rig

Enhancements

Iron Roughneck : NOV IR-3080-55-AHM

Mud System

Mud Pumps : 2 ea NOV F-800

Power Rating : 800 hp @ 150 spm

Reserve Mud Volume : 0 bbls

Pressure Rating : 5,000 psi

Active Mud Volume : 700 bbls

Shale Shakers : 2 ea. MI Swaco

Desander : N/A

Desilter : N/A

Mud Cleaner : N/A

Centrifuge : N/A

Well Control

Choke Manifold : 2 1/16" 5,000 psi

BOP Closing Unit : Control Technology, 5 station 3,000 psi

|  |

| |

|

Id: WR1038

1200T SWL Pedestal Crane - For Sale

Worldrigs ID: WR1038 Description :

Principal Particulars :

Maker : NOV/Am-Clyde

Class : DNV incl. man riding

Crane Voltage : 690V, Crane equipped with 6,6 KV transformers

Crane Capacities :

Capacity Main : 1200t@14-31m,600t@50m, 250t@70m

Capacity Aux : 500t@20.3-60m, 120t@100m

Capacity Whip : 50t@22.9-113.4m

Man-riding Capacity : 5 ton all radii

Boom Length (from center line of boom foot pin) :

Length to main fall upper block sheaves : 85.5m

Length to auxiliary fall upper block sheaves :107.0m

Length to whip fall jib tip sheaves :115.0m

Operating Radius :

Main fall : 18.0-91.0m

Auxilliary fall : 20.0-105.0m

Whip fall : 22.55-113.41m

Winches :

Main hoist winch : 66.8 MT single linepull at 64m/min, 4x186 KW

Aux hoist winch : 68.7 Mt single linepull at 62m/min, 4x186 KW

Whip hoist winch : 27.5 MT single linepull at 158m/min, 4x186 KW

Boom hoist winch : 2.3 MT single linepull at 26-61m/min, 3x186 KW

Swing drives : 6x149 KW, Swing speed 0,3 RPM

Tugger winches, 4xload control : 25 MT single line at 16m/min,75 KW each

|  |

| |

|

|

|

Id: WR706

Drillmec MR-8000 Semitrailer Rig for Sale

Worldrigs ID: WR706

General Rig Data

Rig Data

Year of Construction : 2008

Year of recertification : July 2016 (for one year certification)

Static hook load :200mt

Setback capacity : 113mt

Mast Data

Make : Drillmec

Type : Four legs, open face, two-section telescopic

Clear height from ground level : 36 meter

Clear height from drilling floor : 31 meter

Substructure

Drill floor height : 5.2 meter

Clear height under rotary beam : 4.2 meter

Drilling floor dimensions (meter x meter) : 7 x 5

Drawworks

Make : Drillmec

Type : Conventional

Rated input power (HP) : 1.080

Main drum make : Drillmec

Main drum size (inch x inch) : 26" x 42 1/2"

Main drum static capacity : 24 mt

Main drum clutch : 42 VC 650

Main drum grooved for line OD (inch) : 1 1/8"

Make-up cathead (make) : Drillmech

Break-out cathead (make) : Drillmech

Drill line : 1 1/8" 6 x 19 IWRC EIPS

Brake type : Brake Band

Hydromatic Auxiliary brake make/model : Parmac / V80

Hydromatic Auxiliary brake capacity : 5.000 hp

Hydromatic Auxiliary brake max. pressure : 15 psi

Hydromatic Auxiliary brake max. speed : 1.550 rpm

Hydromatic Auxiliary brake clutch : 26CB 525

Cooling fluid : Water

Crown-O-Matic device : Yes Drillmec

Compound

Air System make : Drillmech

Air compressor engine : Ingersoll Rand T30 mod 2475

Air compressor max. working pressure : 11 bar

Air compressor max. HP in max. WP : 7.1 hp

Air tank capacity : 500 lt

Hydraulic system make : Drillmech

Power Pack

Diesel Engine make/model : Caterpillar / C15 - ACERT

Diesel Engine hoisting power : 540 hp

Diesel Engine quantity : 2 ea

Diesel Engine rate : 2.100 rpm

Automatic gear box quantity : 2 ea

Torque converter : TC680

Hoisting speed : 5 + 1 reverse

Rotary Drive and Rotary Table

Make : Drillmec

Rotary table opening : 271/2"

Max static load on table : 320 mt

Rotary air brake : 16 CB 500

Rotary clutch : 20 CB 500

Hydraulic Winch

Max. Load pull on drilling floor : 3.000 kg

Max. load pull on semi trailer : 5.000 kg

Drilling Equipment

Travelling block - Hook make : American block or equivalent

Travelling block - Hook Working load capacity : 226 mt

Swivel make/model : King Oil Tools/ 6SX or equivalent

Swivel static capacity : 200 mt

Swivel rotating capacity (at 100 rpm) : 122 mt

Swivel working pressure : 345 bar

Hydraulic elevation BOP make : Drillmec

Hydraulic elevation BOP total lifting capacity : 20 ton

Rig Instrumentation

Dead line anchor single pull capacity : 22.6 mt

Dead line anchor load sensor : E80 Tension

Mud System

Make : Drillmec

Volume of shale shaker tank : 60 m3

Volume of intermediate tank : 46 m3

Volume of suction tank : 46 m3

Volume of mixing tank : 60 m3

Water tank : 40 m3

Triplex Mud Pump

Make/Model : Drillmec / 9T1000

Quantity : 2 ea

Design : Horizontal design as per API 7K

Rated Input (HP) : 1.000

Valve Pot size : 7

Mounted on : Oilfield skid

Diesel Engine for Mud Pump

Make/Model : Caterpillar C18 Acert

Engine power : 600hp @ 1.200 rpm

Quantity : 2 ea for each mud pump

Transmission for Mud Pump

Make/Model : Drillmec/TC955 Torque converter

Pulsation Dampener

Make/Model : Hydrill K20-5000 or equivalent

Quantity : 1 ea (for each pump)

Shale Shaker Tank

1. Shale Shaker

Make/Model : Swaco/Mongoose PT

Quantity : 2 ea

Electric motor : 400V - 50Hz ex-proof

2. Mud Cleaner

Make/Model : Swaco / 2-12/6T4/Mongoose PT

Quantity : 1 ea

Electric motor : 400V - 50Hz ex-proof

3. Degasser

Make/Model : Swaco / Vacuum Degasser horizontal type

Quantity : 1 ea

Electric motor : 400V - 50Hz ex-proof

4. Mud Agitators

Make/Model : Swaco / c/w blades

Quantity : 2 ea

Electric motor : 15 KW 400V - 50Hz ex-proof

Intermediate Tank

Centrifugal Pump

Quantity : 2 ea

Used for : Solid equipment

Electric Motor : 75 kW 400V - 50Hz ex-proof

Mud Agitators

Quantity : 2 ea

Electric Motor : 15 kW 400V - 50Hz ex-proof

Suction Tank

1. Supercharging Centrifugal Pump

Quantity : 2 ea

Electric Motor : 75 kW 400V - 50Hz ex-proof

2. Mud Agitators

Quantity : 2 ea

Electric Motor : 15 kW 400V - 50Hz ex-proof

Mixing Tank

1. Mud Agitators

Quantity : 2 ea

Electric Motor : 15 kW 400V - 50Hz ex-proof

Mixing Unit

1. Centrifugal Pump

Quantity : 2 ea

Used for : Solid equipment

Electric Motor : 75 kW 400V - 50Hz ex-proof

2. Hoppers

Quantity : 2 ea

Size : 6"

Trip Tank

1. Quantity / Equipped with : 1 ea / 6 m3 w/ centrifugal pump & electric motor

Poor Boy Degasser

1. Quantity : 1 ea

(Mounted on top of the trip tank complete with inlet and outlet pipes)

Power System

Power Generator

Make/Model : Caterpillar / C15

Quantity : 2 ea

Prime Power : 400ekW-453kW

Frequency : 50 Hz

Speed : 1.500 rpm

MCC- Switch Gear Panel

Quantity : 1 ea

MCC for mud system : 400V / 50Hz

MCC for lighting system : 220V / 50Hz

Air Unit - Utility House

Electric Air Compressor

Pressure at discharge with dryer : 9.8 bar

Pressure at discharge without dryer : 10 bar

Capacity : 95lt/s

Power : 37kW-400V/50Hz

Quantity : 2 ea

Auxiliary Equipment

Water Cooling System

Water Tank Capacity : 5 m3

Water pump flow : 30 m3/h

Water pump motor : 400V/50Hz ex-proof

Quantity : 1 ea

Fuel Tank

Capacity : 60 m3 + 5 m3

Quantity : 1 set

Hydraulic Top Drive (HTD 220)

General Information

Make : Drillmec

Quantity : 1 ea

Bore : 3"

Rated circulating pressure : 5.000 psi - 35 Mpa

Hydraulic system requirement : 868 lt - 35 Mpa

Auxiliary hydraulic system : 225 lt - 55 Mpa

Circulation Swivel

Make : Drillmec

Wash Pipe ID : 3"

Max. WP : 350 bar

Quantity : 1 ea

Rotating Double Hook

Make : Drillmec

Quantity : 1 ea

IBOP Valve

Make : Drillmec

OD : 7 3/4"

ID : 3 1/6"

Working Pressure : 345 bar (5.000 psi)

Quantity : 1 ea

Connection : NC50 box & pin

Top Drive Hydraulic Power Unit

Quantity : 1 ea (Container)

Diesel Engine Quantity : 1 ea

Diesel Engine Make/Model : Caterpillar / C15

Diesel Engine power : 540 hp

Diesel Engine speed : 1.800 rpm

Diesel Engine no. of cylinder : 6 in line

Top Drive Rails

Quantity : 4 ea

Rig Floor Equipment

1. D.P. and D.C. Rotary Tongs

Quantity (no.) : 2 ea

Type : Rotary

Range size from : 3 1/2"

Range size to : 14 3/8"

2. Elevator Links

Set : 1 ea

Length, 1 set : 2 1/4" x 108"

Rated capacity : 250t

Drilling Instrumentation

Drilling Console

Weight Indicator

Mud Pump Pressure Gauges : Pressure range (0-5000 psi)

Rotary Torque Indicator

Rotary speed Tachometer : For top drive

Tong Torque Indicator

Mud Pump Stroke Indicator (Qty) : 2 ea

Others

Dog House (Drillmec made) : 1 ea

Dog House Support : 1 ea

High Pressure Ground Line : 1 ea

Monkey Board : 1 ea

Mud Tanks Walkways : 8 ea

Carrier Walkways : 12 ea

Handrails : 39 ea

Rotary Hose : 1 ea

Mud Pump Discharge Hose : 2 ea

Exhaust : 2 ea

Cable Tray : 1 ea

Suction Line : 1 ea

Stand Pipe Manifold : 1 ea

Stairs : 5 ea

Power Tong & Power Tong Support : 1 ea

BOP Lifting Device Remote Control Panel : 1 ea

Bop Skid & Bop Trolley : 1 ea

Vee Door : 1 ea

Driller Panel : 1 ea

Drilling Recorder 8 Pen : 1 ea

Rig Lightening System : 1 ea

Mud Tanks Lightening System : 1 ea

Well Control Equipment (without valid Certificate) : 1 ea

- 1 ea x 13 5/8" x 5000 psi Annular (Bag Type) BOP

- 1 ea x 13 5/8" x 5000 psi Double Ram BOP (Cameron "U" Type)

- 1 ea x 13 5/8" x 5000 psi Drilling Spool

- 1 ea x 3 1/8" x 5000 psi Armor Covered Flexible Hose

- 1 ea x 3 1/8" x 5000 psi Choke Manifold

- 1 ea x 3 1/8" x 5000 psi Closing Unit

- 1 ea x Remote Control Panel

- 1 ea x Remote Choke Control Panel

- 1 ea x 3 1/8" x 5000 psi HCR Valve

|  |

| |

|

Id: WR941

CME 45 Auger Drilling Rig - For Sale

Worldrigs ID: WR941 Description :

1978 CME 45 Drilling Rig Truck - Serial: 123884

Ford 4 Cylinder Gas Engine

Hours : 358

Auto Hammer

2 winch lines

22ft 4" auger sections

5ft 8" auger sections

23ft 5ft boring rod extensions

8" rock bit

4" rock bit

8" auger bit

Mounted on a 1997 Ford F450 Super Duty - VIN: 1FDLF47F8VEB32264

Miles : 235,967 on odometer

7.3L Power Stroke Diesel Engine

Manual 5 Speed Transmission

Suspension : Spring

Brakes : Hydraulic

GVWR : 15,000 lbs

Wheelbase : 161" & Tire Size: 235/85R16

Location : USA

|  |

| |

|

Id: WR1118

Atlas Copco T35R Surface Drilling Rig - For Sale

Worldrigs ID: WR1118 Description :

2011 Atlas Copco T35R Surface Drill Rig

Diesel Engine

Remote Controlled

Runs T51 Drill Pipe

Under 5,000 Hours

Location : USA

|  |

| |

|

|

|

Id: WR930

Ingersoll-Rand Range II RD20 Drilling Rig - For Sale

Worldrigs ID: WR930 Description :

2000 Ingersoll-Rand Range II RD20 Drill Rig - Serial#: 6599

Cummins QSK19 Diesel Deck Engine

IR 1250 CFM - 350 PSI HR2.5 Air Compressor (Clutch)

110,000 lbs of Pullback

Hydraulic Leveling Jacks

Mounted on a CCC (Crane Carrier Chassis) Truck

Diesel Engine

4 Axle VIN#: 1CYDEM480YT044734

Tooling Included :

1 - 12" DTH Hammer

50 - Drill Pipe (30ft x 4-1/2" x 2-7/8" IF)

Fork Wrenches, Shocks and Elevator

Newer Paint

Location : North America

|  |

| |

|

Id: WR935

Crown 750 Trailer Mounted Drilling Rig for Sale

Worldrigs ID: WR935 Description :

General Description :

Make : Crown

Year Built/Rebuilt : 2006

Rated HP : 750

Mast :

Height : 118ft Guyed

Static Hook Load Capacity : 350,000#

Mast Racking : 4-1/2"Pipe

Substructure :

Style : Scoped

Height : 16.00 ft

Drawworks :

Make : Crown

Power Rating : 750 HP

Input Power : 2 Cat C-15

Power Generation :

Engines :

2 john Deer

6Cyl

Generators :

2 Marathon

400KW

Mud System :

Mud Pumps : 2 1000 HP

Model : F 1000 Triplex

Pressure Rating : 5,000 psi

Shale Shakers : 2 Derrick Linear

Desander : 2 Cones

Desilter : 12 Cones

|  |

| |

|

Id: WR1041

Chicago Pneumatic T650WS Drilling Rig - For Sale

Worldrigs ID: WR1041 Description :

1978 Chicago Pneumatic T650WS Drill Rig

GHH 825 cfm / 300 psi Air Compressor

CAT 3406 Diesel Deck Engine (recently install reman head on deck engine)

2 Piston Bean water injection pump

Hammer lubricator

300 Ft of drill pipe (20ft mix) - 4” & 4-1/2” mixed & 20 ft 3-1/2" Thread

Mounted on Ford Truck - VIN#: U81QVCC9241

CAT 3208 Diesel Engine

Note: Bill of Sale only & no title available

Location : USA

|  |

| |

|

|

|

Id: WR933

Schramm TXD 200 Trailer Mounted Drilling Rig for Sale

Worldrigs ID: WR933

Description :

2007 Model TXD200 Schramm Unit 138 Ser # J135-0106

MTU 12V2000 Engine Ser # 5352005063

Sub Base/Mud Boat 2 Piece 61ft 5"L x 10ft 6"W x 2ft 7"H

Tag Axle Vin # 1K9AL10A872268004

Schramm LoadSafe 2011 Model Unit 7232 Vin# 4S9S1PA25BW276002

Location : USA

|  |

| |

|

Id: 9000-420

Drillmaster 1200M Drill Rig for sale

Worldrigs ID: WR422 Drawworks:

DRILLMASTER 1200M New (2009) Single Drum Drawworks, 1,200 Hp

Lebus grooved for 1-1/4” Drilling Line, Hydraulic operated Makeup

& Breakout winches, Over-Running Clutch, Air Driller’s Console, Crown-O-Matic standard chain drive for rotary table.

Compound:

2-Engine, In-Line Compound For rotary & Drawworks drive.

BRAKE:

Superior 4 section 60” Hydromatic Brake

Drawwworks Power:

No. 1 – CATERPILLAR C-18 Diesel Engine S/N# WJH01256,

600 Hp Rated, w/24 Volt Electric Start, Radiator, Gauges,

Allison S-6610 6 speed transmission Air clutch

Hours# 18,307

No. 2 – CATERPILLAR C-18 Diesel Engine S/N# WJH01260,

600 Hp Rated, w/24 Volt Electric Start, Radiator, Gauges,

Allison S-6610 6 speed transmission Air clutch

Hours# 17,854

Hydraulic power unit 40HP for tong winches and boom line winch

Mast:

DRILLMASTER New 2009 SN#09864 20’1 1”W x 136’H Cantilever Mast,

With a Gross Nominal Capacity of 915,000 Lbs. and a

650,000 Lb. Static Hook Load, Max wind 91 Knots,

with ten (10) lines. Crown Block w/ (5)42” Sheave Cluster &

1-56”Fast line Sheave grooved for 1-1/4” diameter drilling line.

Each Crown Sheave wire rope groove is flame hardened.

Each Crown Sheave is fitted with Timken roller bearings and grease seals.

Derrick complete with Crown Safety Platform, 20 finger Racking Board W/ electric mule, Bridal Lines, Tong Counter Weights, Survey Line Sheaves,

Tugger Sheaves, Ladder, Derrick Climber, Geronimo line,

4” Standpipe & Manifold and Derrick Stand.

Last Certification 8/23/2009

Substructure:

DRILLMASTER New (2009) 29’10”W x 20’H x 48’8”L

(4) Box-On-Box Substructure w/ Rotary Beams, V-Door Ramp,

Stairs, (2) Air Receiver Tanks, NATIONAL Deadline Anchor, Hydraulic power unit 40HP, Safety Rails, inside Catwalk Trolley, 7’W x 14’L built in Tool

Room (ODS) (3) Stairs, Outside wall Winterized, Jacking door,

12’ X 12’ Setback spreader, internal stairway, Vapor proof lighting,

Skidded with oilfield tail rolls

Pump: (Primary)

CNPC Equipment F-1000 Triplex Mud Pump New 2009,

S/N BZ11-040E, 1,000Hp.

w/ LANZOU Pulsation Dampener

MF 5,000 Psi. Pressure Gauge

FIVE STAR 6”x8”x14” Charging Pump p/b TECO 75 Hp. Electric Motor,

Chinese 3”Shear Relief Value, Master Skidded w/ (2) Engines belt compound

Pump Power

CATERPILLAR C-18 Diesel Engine S/N WJHO1709,

575 HP w/24 Volt Electric Start, Radiator, Gauges,

V-Belt Drive EATON 18CB500 Air Flex Clutch,

Mounted Pump Master Skid.

Hours # 14,911

CATERPILLAR C-18 Diesel Engine S/N WJH01683,

575 HP w/ 24 Volt Electric Start, Radiator, Gauges,

V-Belt Drive EATON18CB500 Air Flex Clutch,

Mounted Pump Master Skid

Hours#14,859

Pump (Secondary):

CNPC Equipment F1000 Triplex Mud Pump New 2009,

S/N BZ11-024E, 1,000 Hp.

w/ LANZHOU Pulsation Dampener ,

MF 5,000 Psi. Pressure Gauge

FIVE STAR 6” x 8” x14” Charging Pump p/b WORLDWIDE 75 Hp. Electric motor,

3” Shear Relief Valve, Master Skidded w/ (2) Engine belt compound

Pump Power

CATERPILLAR C-18 Diesel Engine S/N WJH-1696,

575 HP w/ 24 volt Electric Start, Radiator, Gauges,

V-Belt Drive, EATON 18CB500 Air Flex Clutch,

Mounted pump Master Skid.

Hours#14,188

CATERPILLAR C1-8 Diesel Engine S/N WJH-1713,

575 HP w/ 24 Volt Electric Start, Radiator, Gauges,

V-Belt Drive, EATON 18CB500 Air Flex Clutch,

Mounted Pump Master Skid.

Hours#14,209

Rotating Equipment:

ROTARY TABLE

Liberty RT-275, New 2009, complies with API split master bushings,

W/ chain drive sprocket, 500 Ton capacity

Swivel:

Ideco 450

Kelly:

5-1/4” x 42’ Hex Kelly W/ HDS Kelly Drive Bushing

Kelly Spinner

OWI 1500 Kelly Spinner S/N 00474B w/ (2) Air Motors,

Kelly Valves:

Upper Kelly Valve.

Lower Kelly Valve

Traveling Equipment:

Sentry Rig Equipment Company

350 Ton Capacity New 2009

4G350 Traveling Block w/ (5) 36” Sheaves, 1-1/4” Line,

Unitized “Hydra-Hook” 350 Ton Capacity

Blowout Preventer & Valves:

1 EACH -13-5/8" X 5000# Jiangsu Xianz hong Petroleum

Double Gate BOP, Top & Bottom Stud configuration

Including - 1set of 5" Pipe Rams Blocks & 1set of Blind Rams,

With 2 - 4" outlets on each side of Body of BOP

1 EACH - 13-5/8" SHAFFER ANNULAR BOP

Includes rubber element

1 EACH - 13 5/8" X 5000# Type D DRILLING SPOOL W/ - 2" SIDE OUTLET & 3" SIDE OUTLET

[MATCHED TO CHOKE MANIFOLD

1 EACH - CHOKE MANIFOLD - 3" X 5000# COMPLETE

INC - STEEL FLEX LINE W/ FLANGES TO CONNECT

TO BOPS OR DRILLING SPOOLS

Closing Unit:

2008 Jiangsu Xianz hong Petroleum Model FXQ640-6

Closing Unit Accumulator, 6 Station,

Rig Floor Controls and monitor panel,

Complete W/ 15 Bottles, 30 HP Cat 3517 Charge Pump, 2 Air Pumps, & set up for Nitrogen Bottle Backup

Suitcase Closing Unit Skid 7’-1 0” x 35’ with junk basket

Choke Manifold & Valves:

Jiangsu Xianz hong Petroleum Choke Manifold w/ (1) 5-Way Cross, (3) 4-1/16”x 5M

Gate Valves, (4) 2-9/16” x 5M Gate Valves, (1) Manual

Adjustable Chokes, Hydraulic Adjustable Chokes, Mounted Oil Field Skid.

W/ 2 Kill Valves- & 2-Choke Valves mounted at drilling spool

Rig Houses:

Dog House,

DRILLMASTER 9’ 1 1”W x 39’ 1 1”L

Doghouse / Change house Combination w/ 17’5”L

Driller’s House w/ Knowledge Box (5) Lockers, Bench Storage, Heater, Lights.

5’L Breezeway, 1 7’5”L Change House, w/Bench Storage, (16-Lockers,

Cabinets, Heater & Lights. Oil Field Skidded.

Generator/Utility Houses:

DRILLMASTER 1 1’10”W x 37’9”L x 11’ 6” T

Utility House w/Lights, Oil Field Skidded to include the following items.

No #1 380 Kw. AC CATERPILLAR Generator Package Powered by Caterpillar C-15 Diesel Engine S/N JRE01987 w/ 24 Volt Electric Start, Radiator, HD Air cleaner Gauges. Marathon 572RSL4025 Generator End SN# 554268-1106, complete with Oil Field skid.

Hours# 14,574

No #2 380 Kw. AC CATERPILLAR Generator Package Powered by Caterpillar C-15 Diesel Engine S/N JRE01970 w/ 24 Volt Electric Start, Radiator, HD Air cleaner Gauges. Marathon 572RSL4025 Generator End SN# 554273-1106, complete with Oil Field skid.

Hours# 15,717

NO. 1 GARDNER-DENVER EBE99N New 2006

Electro Saver II Rotary Screw Air Compressor S/N# S237421,

P/b TOSHIBA 30 Hp. Electric Motor, Mounted 240 Gallon Horizontal Tank.

Hours# 15,128

NO. 2 GARDNER-DENVER EBE99N New 2006

Electro Saver II Rotary Screw Air Compressor S/N# S237419,

P/b TOSHIBA 30 Hp. Electric Motor, Mounted 240 Gallon Horizontal Tank.

Hours# 14,400

SIEMENS Interlock Panel, 600 Amp 480 Volt Main Lockout Disconnects breakers.

ALLEN BRADLEY Electrical Load center with magnetic starter & breakers,

SQUARE D 225 amp 240 volt panel with breakers

SQUARE D 75KVA Transformer 480 volt to 240 volt

DRILLMASTER 7’9”W x 13”H x 43’1”L Electrical

Suitcase.

DRILLMASTER 2’5”W x 1 3”H x 36’3”L Electrical

Suitcases.

Mud System:

DRILLMASTER 9’6”W x 7’H x 34’5”L, 394 Bbl. Suction Tank

10’L Covered Porch, (3) Compartments,

(3) MAX 2000 Mud Agitators p/b TECO 25 Hp. Electric Motors,

Sloped Bottom, Top Mounted Walkways, Safety Rails, Lights, Oil Field Skidded.

FIVE STAR 6”x8”x14” Centrifugal Mixing Pump S/N 5284, p/b BALDOR 75 Hp. Electric Motor.

FIVE STAR 6”x8”x14” Centrifugal Mixing Pump S/N 5284, p/b BALDOR 75 Hp. Electric Motor.

With internal jetting system, 3 dump gates.

DRILLMASTER 9’6”W x 7’H x 34’7”L, 394 Bbl. Shaker Tank

10’L Covered Porch, (3) Compartments

MAX 2000 Mud Agitator Agitators p/b TECO 25 Hp. Electric Motors,

Sloped Bottom, Top Mounted Walkways, Safety Rails, Lights, Skidded.

With internal jetting system, 3 dump gates.

FIVE STAR 6”x8”x14” Centrifugal Mixing Pump S/N

5269, p/b BALDOR 75 Hp. Electric Motor.

FIVE STAR 6”x8”x14” Centrifugal Mixing Pump S/N

5283, p/b BALDOR 75 Hp. Electric Motor.

SHALE SHAKER, Fluid Systems Inc., Single Screen,

Linear Motion Shale Shaker S/N2450,

SHALE SHAKER, Fluid Systems Inc., Single Screen,

Linear Motion Shale Shaker S/N3089,

NOI DSN-ZH-10CTX Desander S/N 8714-5732,w/ (2) 10” Cones.

NOI DSL-10GG-4CTX Desilter S/N 8714-5731,w/ (10)4” Cones.

DRILCO “Deep Pit” Degasser p/b TECO 10 Hp. Electric Motor

Bubble Buster: Geothermal Type Bubble Buster

Mud House:

DRILLMASTER 9’ 1 1”W x 26’L Mud House w/Mud Hopper, Test Sink, Ventilation Fan, Electric Heater,

Lights, Double Side Door, (2) End Doors, Skidded. Includes 7’H Tri-Stand on one end the other end sets on suction tank.

Fuel Tank:

DRILLMASTER 7’1 1”Wx8’Hx30’L, 13,860 Gallon Fuel Tank

w/ (2) AMT 1/2 Hp. Fuel Transfer Pumps p/b BALDOR 1/2 Hp. Electric Motors,

With Three (3) Compartments, Combo Lubester Oilfield Skidded.

Water Tank:

DRILLMASTER 10’10”W x 8’1”H x 35’L, 529 Bbl. Water Tank

w/ 10’L Covered Extension, Pump Room, OilField Skidded

FIVE STAR 3”x4”x1 1” Centrifugal Water Pump

S/N 5420, p/b TECO 20 Hp. Electric Motor.

FIVE STAR 3”x4”x1 1” Centrifugal Water Pump

S/N5267, p/b TECO 20 Hp. Electric Motor.

Instrumentation:

Weight Indicator

Mud Gauges.

Ancillary Equipment:

DRILLMASTER 5’W x 2’4”H x 60’L, 2-Section Catwalk w/ Steel Deck and stands for string blocks.

Pipe Racks 5 Sets 29” x 30’ 1 set 29” x 12’ 1 set 41” x 30’

FIVE STAR “Retriever” Electric Measuring Device S/N 862, w/ 15,000 Ft. of. 092 Wire line

2 sets drill pipe elevators 5”

2 sets of drill pipe slips 5”

2 sets of drill collar slips 7” & 9”

2 sets tongs with all head for pipe & casing

2 sets of safety clamps

Mud box:

108” 4” elevator bails

Crossover, bottom hole, lifting Subs

Air Hoist Air Wrench, Model HUL40, S/N-REM10370, 9000 lb. Pull Rating

Air Hoist Air Wrench, Model KSUL, S/N-REM13962, 10,500 lb. Pull Rating

4,000 Ft. of 1-1/4” Drill Line, Mounted Spooler Stand

3-1/2” X 5,000 Psi. Rotary Hose

Vibrator Hose 2 Each 3 ½” x 18’

Rat hole

Mouse hole

8 rig matting boards

Small hand tools & wrenches

Fluorescent & Mercury-Vapor Rig Lights & Wiring Explosion proof

Atco Office/ living shack all electric w/ oil field skid

|  |

| |

|

Id: 9000-411

Foremost CTR Single Coil Tubing Hybrid Drilling Rig

Worldrigs ID: WR332 Drawworks

Foremost hydraulic drawworks, 95,000 lb capacity, 400' drum capacity

Drawworks Power

Detroit series 60 floor engine

Hydraulic Power Unit

w/ (5) main hydraulic pumps, hydraulic reservoir, thermal exchanger, plumbing , filters.

Mast

Foremost 85' mast, 140,000 lb maximum hook load w/ (4) lines, 1" drill line, (2) 4 stage

mast raising cylinders, chains, stand pipe, hydraulic piping, utility winch, access ladder,

lighting, fall arrest

Substructure

Foremost trailer mounted raised substructure; sliding trolley ВОРhandler

w/ (2) hydraulic cylinders, manual cellar controls, standpipe valve, steam manifold,

explosion proof lighting, mounted on 2005 peerless Т/Р16 wheel trailer, tires 11 r22.5,

steel buds, spring suspension, w/ rear outriggers, front leveling jacks, hydraulic & electrical

lines"

Rotary Table

16" rotary table, w/ 1,600 lb torque, 140,000 lb maximum load

Top Drive

Fluid design solutions model FDS240T 70 ton hydraulic top drive w/ integrated swivel,

integral traveling block & backup leg

Injector

Steward Stevenson model M1100SK injector, 110,00 lb lifting capacity, 60,000 lb snub

capacity

Hydraulic System & Components

Raising cylinders, winches , bop handler, doghouse raising system, hoses, filters, valves

- (1) set web wilson type aax manual 2 7/8"- 9 5/8" rotary tongs

- (1) drill pipe elevator

- set handling tools - drill pipe, drill collar slips, safety clamp, drill pipe elevators

- townsend type 85 sph annular preventer, 9" Ñ… 3,500 psi

- (2) townsend model Т88 ram preventer, 9" х 3,000 psi

- control tech working spool, 9" Ñ… 3,000 psi, w/ 2" outlets

- control tech crossover spool, 7" Ñ… 3,000 psi

Mud pump

Mastco pump shack, model JBI JF800 triplex mud pump, detroit series 60 14.7 liter

700 ÐÑ€ diesel engine, tool shop

Mud System

358 bbl mud tank, (4) compartments - 17 bbl trip tank, 88 bbl suction tank,

125 bbl settling tank, 125 bbl shaker tank, mix pump, mixing guns, manifold

- swaco mongoose-pt elliptical-motion shale shakers

- (4) mud guns, (9) flow gates & skimmers

- poorboy 28" in-tank degasser w/ 150' of 8" vent line

- chemical mix barrel w/ 5 hp electric motor

- (2) mission model 40202529 6Ñ…5Ñ…11 pumps, w/ 50 ÐÑ€ electric motor, 4" manifold, w/ (7)

4" butterfly valves, hopper, storage compartment, exhaust fan, mud weight station,

pason equipment

Drill Pipe

(196) joints 3 1/2" range 3 grade Е drill pipe, w/ 3 1/2" if connections

- (23) joints 4" range 3 grade Е drill pipe, w/ 3 1/2" if connections

- (10) joints 4 3/4" drill collars, w/ 3 1/2" if connections

- (10) joints 6 1/4" drill collars, w/ 4 1/2" xh connections

- (20) joints 3 1/2" heví-weight drill pipe, w/ 4 1/2" xh connections

Combination Building

12' Ñ… 54' mounted on 4 member skid, electrical switchgear, transformer,

accumulator plumbing, (15) lockers, (2) benches, w/ 9,000 liter fuel tank, (4) product tanks

Generator 1

Stamford model 6063-МК35 350 kw generator, w/ detroit series 60 475 hр diesel

engine, w/ electric start, lockout box

Generator 2

Stamford model IЕС34-1 142 kw generator, w/ john deere 190 hр diesel engine,

w/ electric start, lockout box

- MCC panel, transformer, starters

Accumulator

Control tech model class 3 accumulator, 80 gallon accumulator, 5 station control,

3,000 psi w/ 178 gallon reservoir, PLC remote, Cat model triplex pump

Air Compressor

National compressed air model nca-16-34GSD air compressor, w/ sullair 2

stage air compressor, 200 hp electric motor, 2005 avis welding & fab 600

Instrumentation

Psi receiver, Selectronix model ST-8 instrumentation diesel day tank, liner rack, utility

bench, tooling, storage cabinets, explosion proof lighting weight indicator, rotary torque

gauge, pump pressure gauges, tong line gauges

Safety Equipment

(3) Scott air packs w/ (2) spare bottles, fire extinguishers, welding shields, safety glasses, first

aid kits, stretcher, eye wash stations, safety signs, lanyards general rig tooling, consumables,

rig supplies, spare parts

Doghouse

9' Ñ… 14', drillers control console, instrumentation, storage cabinets / bench, stabbing valve,

ruffneck heater, Ð/С, shelving

Tool House

314 bbl water tank, access stairs, safety rails, lubster, cat model 310 triplex wash pump, utility

bench, fastener bins, ruffneck heater, storage compartments, tooling

Crew house 2005 shelter rig manager's wellsite: 11.5' x 45', crew washroom, storage area, desk,

couches , fridge, stove, washer, dryer, washroom, sleep area

Hydraulic Catwalk w/ operator enclosure, integral hydraulic power unit, (4) swing out arms,

(4) leveling jacks, hydraulic pump w/ 50 hp electric motor, (3) hydraulic pipe tubs w/ controls,

manifold 2048-F

Choke & Kill Line Valve, 2" x 3,000 psi w/ Hi-Kalibre HCR, manual gate valves, check valves